Amidst pressing plastic recycling concerns and the imminent 2024 UN plastic pollution treaty, Saudi Arabia directs attention to circular carbon economy solutions and innovative technologies like supercritical water gasification (SCWG). SCWG operates under extreme conditions—temperatures exceeding 374°C and pressures surpassing 221 bars—transforming water into a state that combines liquid and gas properties, ideal for plastic waste conversion. Within these conditions, SCWG yields hydrogen-rich syngas while minimizing byproducts. Our research unites experts to decipher SCWG, detoxify plastic, optimize hydrogen production, and enhance circular economies. SCWG holds potential for valorizing mixed plastics from municipal solid waste (MSW). Our objectives encompass advancing SCWG through scientific fundamentals, experimentation, lab-scale optimization, and creating self-sustaining high-hydrogen syngas processes, supported by modeling and analysis tools.

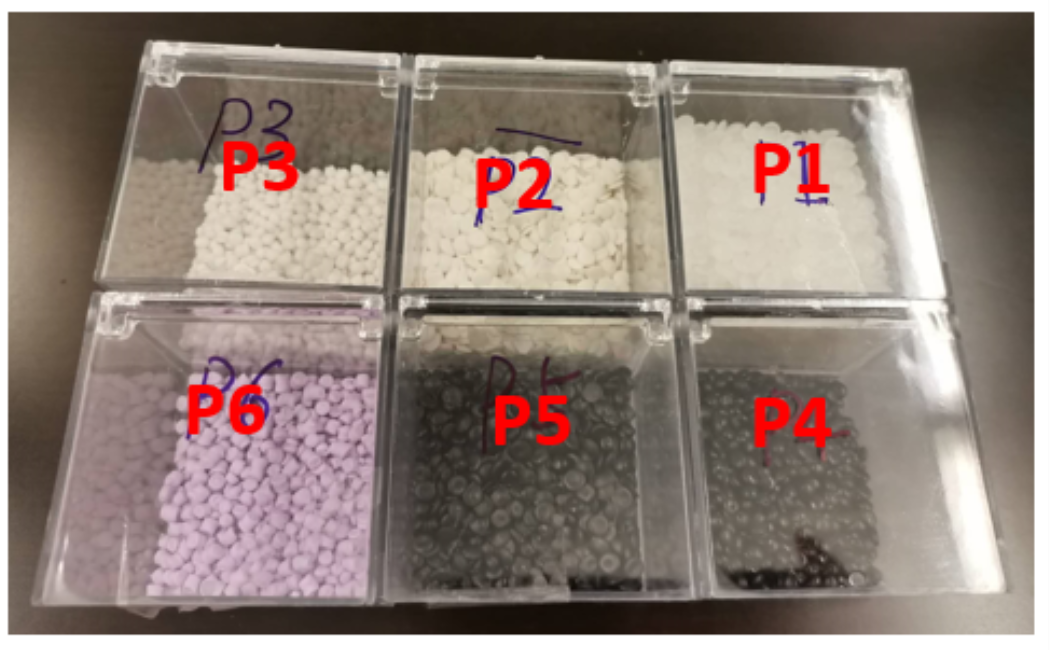

Figure 1: Pellets of mixed plastics waste received from KAUST Recycling Center.

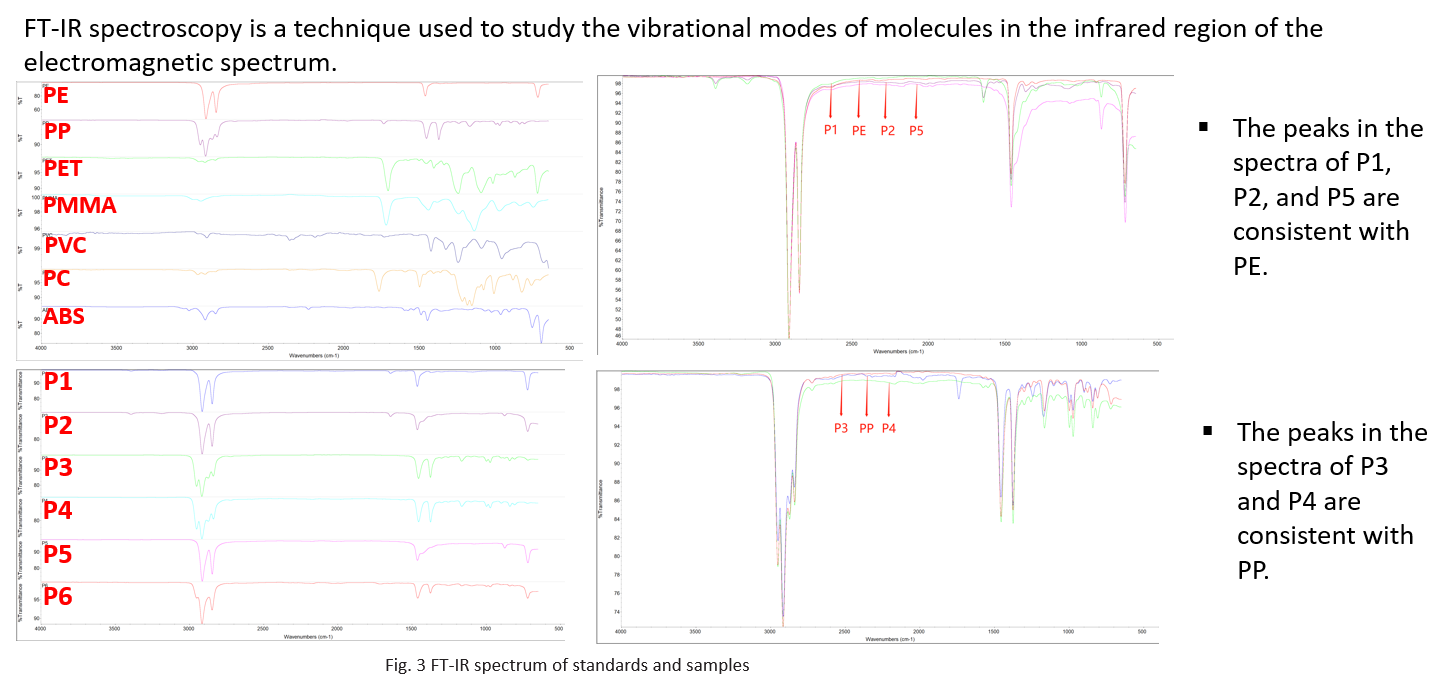

Mixed plastic waste from KAUST's municipal solid waste (MSW) arrives in pellet form from the Materials Recycling Facility, followed by thorough analysis to identify its constituents. Utilizing techniques such as Raman spectroscopy, Fourier Transform Infrared (FT-IR) spectroscopy, Differential Scanning Calorimetry (DSC), Pyrolysis GC-MS, and GC-MS, we identify the molecular composition. Additionally, we employ comprehensive characterization methods including CHNS-O analysis, X-ray Fluorescence (XRF), Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES), Thermogravimetric Analysis-Mass Spectrometry (TG-MS), and Pyrolysis GC×GC-TOF/MS.

Figure 2: Identification of plastic samples-FT-IR.

Table 1: Plastic waste samples from KAUST were identified using advanced analytical and imaging characterization methods at KAUST Core Labs.

| Sample | Compound | Structure |

|---|---|---|

| P1 | Poly (ethylene), low & high density, LDPE & HDPE | [−CH2−CH2−]n |

| P2 | Poly (ethylene), high density, HDPE | [−CH2−CH2−]n |

| P3 | Poly(propylene), PP | [−CH2−CH(CH3) −]n |

| P4 | Poly(propylene), PP | [−CH2−CH(CH3) −]n |

| P5 | Poly (ethylene), high density, HDPE | [−CH2−CH2−]n |

| P6 | Low density Poly (ethylene) (LDPE) & high density Poly (ethylene) (HDPE) & Poly(propylene) (PP) | [−CH2−CH2−]n & [−CH2−CH(CH3) −]n |