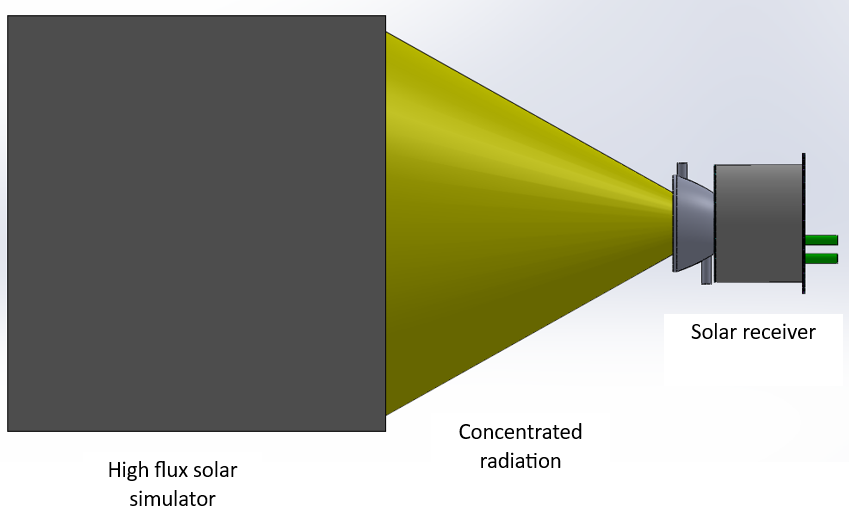

Current commercial solar receivers are subject to a non-uniform radiation. The heat flux along the tubes is non-linear, with circumferential variations, which induce high thermal stress. Indeed, a limiting factor to heat flux is thermal stress in the heated receiver tubes that accounts of the temperature difference between irradiated front and concealed back tube side, observed as a bending moment. This temperature difference is higher for the case of gases than for the case of molten salt.

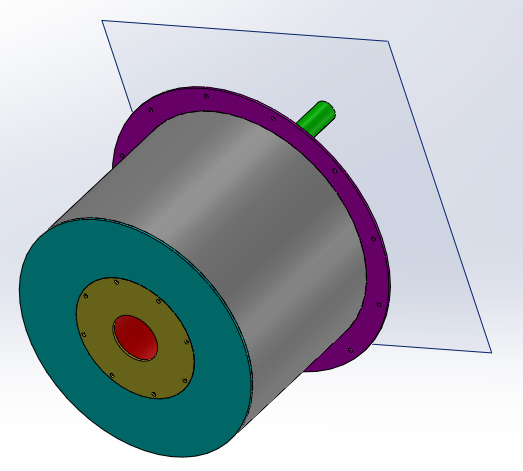

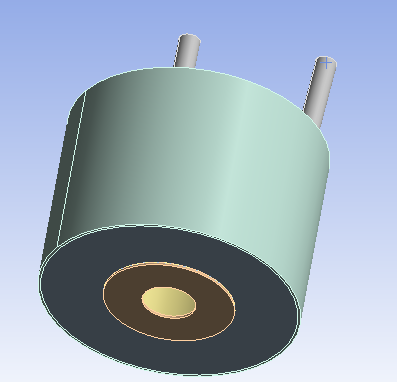

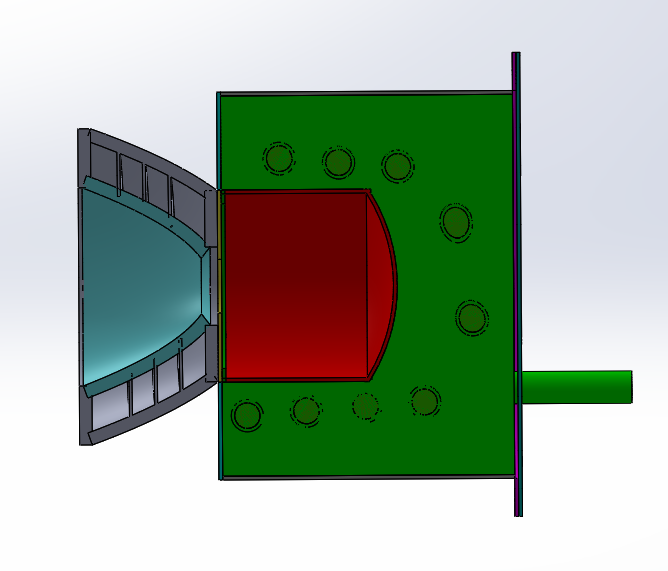

To solve these issues, we are designing, fabricating, and testing a solar cavity receiver with molten metal bath. The molten metal has a very high conductivity, absorbs concentrated solar radiation and provides a uniform heat flux distribution around the tubes of the solar receiver. This eliminates the thermal stress observed in the current commercial solar receivers. Due to its high thermal mass, the molten metal bath also plays a role of an energy storage medium during cloud passage and during a sharp variation of solar radiation, which significantly reduces the thermal cycling and increases the lifetime of the solar receiver.