Our group is developing a steam calcination process that uses green steam to calcine different types of ores, such as calcium limestone, gypsum, and bauxite. Steam lowers the decomposition temperature of the ore and acts as a catalyst, accelerating the reaction rate. Additionally, using a sustainable energy source to produce the steam (green steam) can significantly reduce the carbon footprint of the calcination process. Some ores produce CO2 when decomposed (limestone), utilizing steam for calcination would make easier to concentrate and capture CO2 from the effluent gas streams.

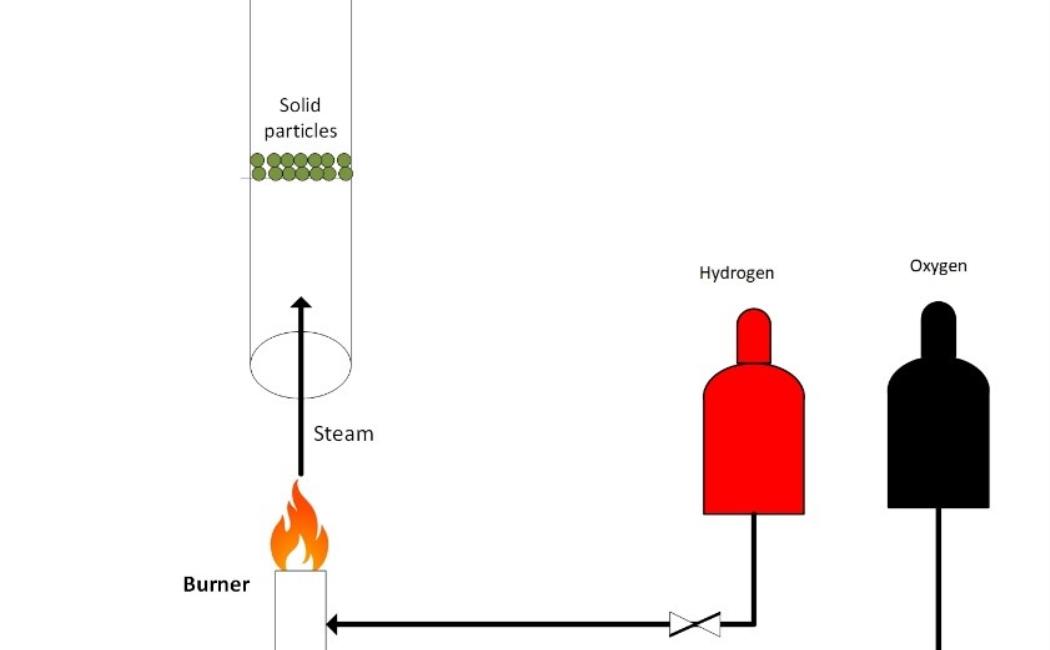

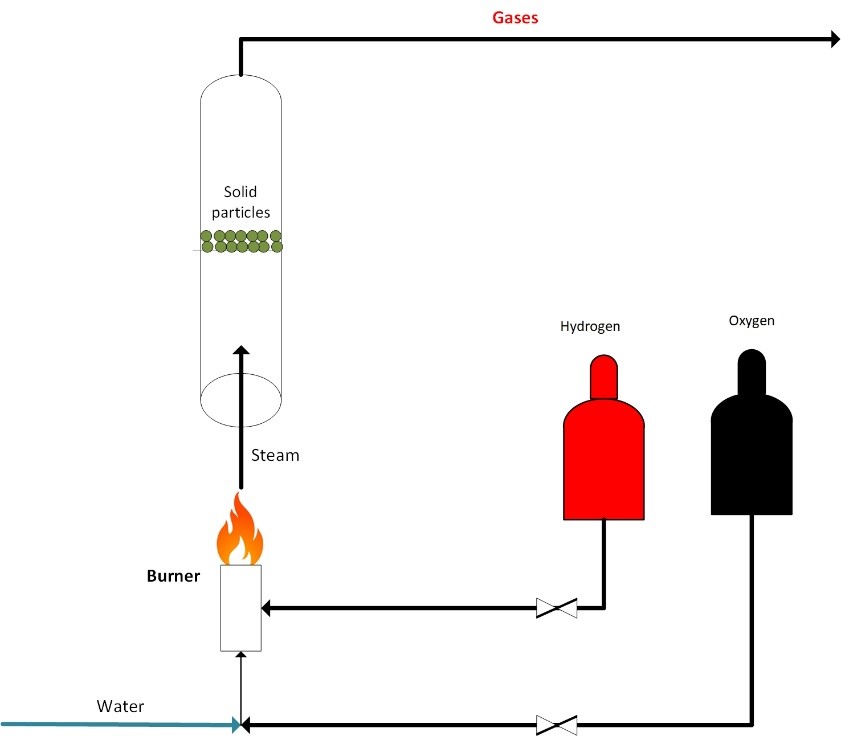

The results showed that steam calcination of calcium sulfate can lower the decomposition temperature by over 200 degrees ⁰C compared to calcination in an atmospheric environment. Figure 1 illustrates the developed steam calcination process. While Figure 2 shows the green steam production process, which has the advantages of zero carbon emissions and high-temperature steam production.

Figure 1: Steam calcination setup.

Figure 2: Green steam production process and efficiency.